Vacuum brazing refers to the use of filler metal (called solder or solder) with a melting point lower than the melting point of the parent material in a vacuum environment. At a temperature lower than the melting point of the parent material and higher than the melting point of the solder, the liquid solder is used in the parent material. A welding method in which the surface of the material is wetted, spread and filled in the gap of the base material, and the base material is dissolved and diffused to achieve the connection between the parts. The parts welded by this process have small deformation and are especially suitable for mass production, and have important applications in aviation, aerospace, automobile, electronics and other fields. In addition, the characteristics of the process also determine that it is particularly suitable for welding special materials such as composite materials, ceramics, crystals, etc., and it is an indispensable process method in the forming and manufacturing of such materials.

1. Characteristics of vacuum brazing

(1)In the whole brazing process, no flux is used, and the parts to be brazed are under vacuum conditions, and there will be no oxidation, carburization, decarburization, pollution and deterioration, and the brazing seam is beautifully formed.

(2)During brazing, the entire part is heated uniformly and the thermal stress is small, the deformation can be controlled to the minimum, and no margin processing and precision brazing can be realized.

(3)Multiple adjacent brazing seams can be brazed at one time, or multiple components can be brazed in the same furnace according to the furnace capacity to improve brazing efficiency.

(4)There are many types of basic metals that can be brazed, especially suitable for brazing aluminum alloys, titanium alloys, stainless steel, high temperature alloys, etc. It is also suitable for composite materials, ceramics, graphite, glass, diamond and other materials.

(5)This broadens the product design approach, and can be used for parts with narrow grooves, extremely small transition tables, blind holes, closed containers, and components with complex shapes. There is no need to consider corrosion, cleaning, and damage caused by fluxes .

2. The main applications of vacuum brazing:

Since the beginning of the 1940s, vacuum brazing technology has become a very promising welding technology. At present, the vacuum brazing process has been promoted and popularized in the fields of aviation, aerospace, atomic energy, electrical instruments, petrochemicals, automobiles, and tools. In terms of aero engine applications, Pratt & Whitney’s JT9D engine honeycomb sealing ring is made of vacuum brazing rings and honeycomb sandwich cores; the engine fuel manifold and stainless steel heat exchanger are composed of vacuum brazing; JTBD engine 12 , 13-stage compressor stator ring is made by vacuum brazing of inner and outer rings and dozens of blades. The engine casing of GE in the United States is also made by three-step vacuum brazing of more than 240 0.25-0.7~ thick Inconel alloy parts. Domestically, Shenyang Liming Engine Company and Chengdu Engine Company have vacuum brazed and some parts are applied to aero engines. In recent years, with the development of science and technology, especially the high-speed development of the home appliance industry (especially the refrigeration industry, including refrigeration equipment such as refrigerators, air conditioners and their three-way and four-way valves), the automobile industry, and the electronics industry, The application of brazing technology is becoming more and more extensive.

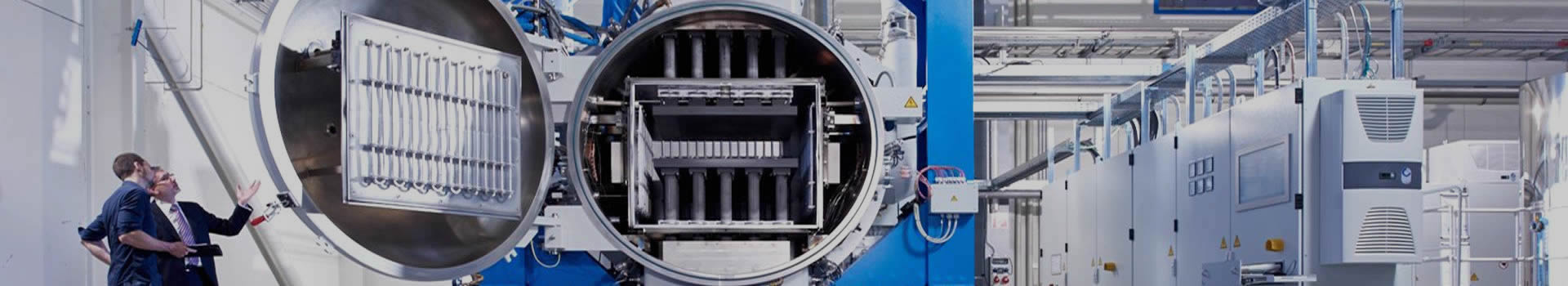

3. Main configuration of vacuum brazing equipment

· Work area size: 800mm (height) × 800mm (width) × 1500mm (length)

· Maximum temperature: 800℃

· Temperature uniformity: ±3℃

· Temperature control accuracy≤±1℃

· Number of control temperature zones: 10 zones

· Working vacuum: 2×10-3Pa

· Furnace capacity: 1000kg